Your cart is currently empty!

Beeswax in Industry

Beeswax

There is nothing quite like beeswax. The unique combination of acids, esters and hydrocarbons along with numerous other substances has resulted in a natural, sustainable material that is remarkably versatile and difficult to replicate.

It has many uses as a pure substance, which most bee farmers know very well, but its versatility becomes evident when it is mixed with other materials such as waxes, resins, polymers, oils, fats, and powdered minerals. When blended with certain materials, the mixture can act as a lubricant, while with others, it becomes an adhesive. Combining beeswax with natural oils and fats will provide the fuel for natural candles, while a mixture with mineral waxes makes an ideal resist for the batik process. Bees have impressive technical skills!

Refining Beeswax

Commercial beeswax refining as we know it today has was born in the 19th century, and grew up in the 20th century. Many of the techniques and processes developed at that time are just as relevant today. In fact, The British Wax Refining Company, which operates the only commercial beeswax refinery in the UK, still uses some of the original equipment that set up the operation in 1914. The techniques employed within the industry to purify and decolour beeswax do vary considerably from one refinery to another. Some of this variation is dictated by the end use, but much of it is simply because there are several ways to achieve the same result.

Most beeswax refiners will use a combination of the following processes:

- Melting and rinsing the wax in boiling water to remove large impurities such as grit.

- Bleaching with acids, peroxides, steam and traditionally, natural sunlight.

- Adsorption of colour and odour with bleaching clays and carbons, followed by filtration.

The key to producing good quality beeswax is to treat it as gently as possible from honeycomb extraction through the whole refining process and allow the natural properties of the beeswax itself to come through.

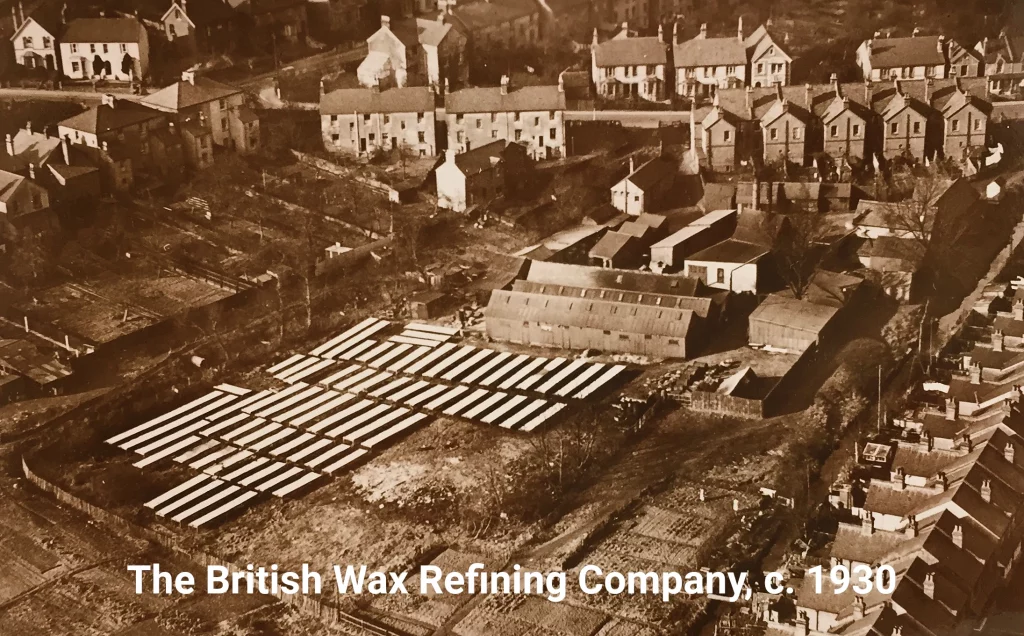

Sun bleaching was the primary means of decolouring beeswax in the first part of the twentieth century. In the picture you can see thin sheets of wax left to bleach in the sun for several weeks.

The British Wax Refining Company, c.1930

Purity

The maximum level of naturally occurring hydrocarbons in beeswax is 14.5%. Hydrocarbon waxes in the form of paraffin wax are routinely added to beeswax for producing foundation sheets in China. As a result, the Chinese beeswax industry has an endemic problem with producing beeswax that will conform to any of the major Pharmacopoeia. The saponification cloud point, also known in the British Pharmacopoeia as the ‘Test for Ceresin and certain other waxes’ is an easy, sensitive method for determining adulteration with hydrocarbons. The method is limited to detecting quantities greater than 1 % of high melting microcrystalline waxes, or more than 4-5% of lower melting paraffin waxes. If the solution becomes clear at or below 65°C, the wax is probably unadulterated with paraffin. However, if the solution turns clear only at a temperature higher than 65°C, the wax is adulterated. Further analysis with Gas Chromatography will show unambiguous level of purity.

Organic beeswax

British Wax is certified by the Soil Association to refine organic beeswax. In order for beeswax to qualify for organic certification, the beeswax must come from a hive situated in an area free from synthetic chemicals such as pesticides, and be produced by bees who have not been treated with antibiotics and most other chemical preparations. Even when certified organic, the majority of commercial users will want assurance that it is technically free from pesticides, and so will require per batch analysis. The costs of analysis and certification, along with the justifiably strict requirements, severely limits the availability of genuine pesticide-free organic beeswax.

As the whole purpose of the organic movement is to limit the environmental impact of synthetic chemicals, there are restrictions on the use of chemicals in the processing of organic beeswax. This limitation has actually resulted in a development within the cosmetic industry where commercial users and consumers are becoming more accustomed to using beeswax in its more natural yellow form than whiter bleached beeswax. The difference manifests itself not only in the colour, but also the smell of the wax. Bleaching beeswax, by any method, tends to remove the more fragrant volatile components of the wax, resulting in the loss of its characteristic honeyed ‘beeswaxy’ smell.

Uses of beeswax

In a few rare and mainly traditional cases such as pure Beeswax candles or waterproofing thread, beeswax is used in its pure form with no additives. However, beeswax is normally blended with other materials to produce a more complex end product.

We use beeswax in our own wax blends when it is appropriate to do so.

Temporary coatings and barriers

Many wax blends perform the function of a temporary coating in industries as diverse as textiles, automotive and food. Being hydrophobic, flexible and non-toxic, and assigned food additive number E901, beeswax is used as a coating for gummy sweets and even slow release dietary supplements for cattle. Mixed with chlorophyll for improved taste, a generous coating of food-grade beeswax will allow the feed supplement to be dispersed through all four of the cow’s stomachs. Meanwhile, an imperceptibly thin coating of vegetable oil and beeswax will stop a bag of gummy bears from turning into a single lump of jelly.

Car, furniture and floor polishes should also be considered temporary coatings, providing a ‘sacrificial layer’ between the object and abrasive elements. Most polishes are complex blends of hard, brittle waxes such as montan and carnauba, modified by more flexible waxes such as microcrystalline wax or beeswax, polymers, natural or synthetic oils and solvents, and silicones. While less commonly used due to its costs, beeswax sometimes plays its part in these formulations due to its compatibility with natural oils and solvents. Many furniture polish manufacturers also like to include beeswax to generate a sense of tradition.

Release agents are another form of temporary barrier. Commercial bakeries use beeswax blends to release baked goods from tins, while certain moulded plastics are released from their moulds with paste and spray waxes, which could double up as furniture polishes.

As mentioned in previous articles, the use of beeswax in personal care products is significant and growing. The fact that beeswax, Candelilla and Carnauba wax can be emulsified and incorporated into water based systems provides the cosmetic chemist with plenty of tools to modify the texture, rheology, stability, application and general ‘feel’ of the product.

The vast majority of the beeswax we refine comes from African bees kept in bark or log hives. During a visit to DR Congo a couple of years ago, I was struck by the effect looking after a few traditional bark hives could have on a rural farming family. Both honey and beeswax are cash crops that generate enough money to buy essential items like salt, blankets or shoes to attend school. I was at a rural hospital looking into starting a beekeeping project when a young teenage boy arrived in a terrible state. He injured his arm while falling from a tree a few days before but, without the money to pay for treatment, his parents had delayed taking him to hospital. As his injury became infected they decided to go to hospital but arrived too late to save him as his body went into septic shock. Could keeping a few beehives have raised their income enough for them not to consider medical treatment a luxury?

British Wax, Tropical Forest Products and other companies dealing in fair and ethical trade aim to respond to these issues by creating products and adjusting the supply chain to provide social benefits to families and whole communities of beekeepers in some of the most rural African communities.

Fuel

The natural and organic movement in particular has created opportunities for beeswax to feature once again as a fuel in candles. In modern natural wax blends, the beeswax tends to be used as a minor functional ingredient to improve the performance of the candle which tends to be based on a hydrogenated natural oil. However, in certified organic candles, beeswax plays a larger part since the palette of natural ingredients is significantly reduced. As consumers become more educated about complex environmental and ethical issues, beeswax is likely to come to the fore as arguably the most environmentally and ethically beneficial candle fuel.

Adhesive

Cut the bark on a pine tree and a sticky resin oozes out. The volatile spirit part of the resin is turpentine. What is left behind is known as colophony, or more commonly, rosin. With the turpentine removed, rosin is hard and brittle at room temperature. However, replace it with a plasticiser such as mineral oil or beeswax, and the mixture becomes useable as a basic hair removal product. Nowadays, there are two main categories of depilatory wax:

‘warm waxes’, which are the consistency of thick honey and are removed with strips;

‘hot waxes’ which are solid at room temperature and have to be melted to be applied.

Beeswax will often form part of the wax component of these mixtures as it adds the right balance of flexibility and stickiness to remove the hair without removing the skin at the same time. We may be a little biased, but waxing done well does not need to hurt more than pulling off a large plaster.

A less well known use of beeswax / resin mixtures is in the manufacture of lenses, from large optical lenses to medical Intra-Ocular lenses used to replace cataracts. These specialist waxes effectively work as a temporary variant on hot melt glue to hold the lenses in place as they are being manufactured.

Surf waxes are an interesting mixture of waxes, resins, oils, polymers and minerals. Rubbed onto surfboards to stop the riders’ feet slipping, they have to provide the right amount adhesion and ‘body’ so that the wax doesn’t smear or leave the feet stuck to the board. Unsurprisingly, this industry is dominated by Australian and Californian companies producing millions of bars per year. However, being generally environmentally conscious, many surfers are turning to surf waxes based on natural ingredients, providing new opportunities for the use of beeswax.

Lubricant

When mixed with fats and oils beeswax can be used as an excellent solid lubricant. One unusual use of solid lubricants is as a bullet lubricant in sports ammunition. A thin coating of our beeswax blend on the tip of bullets is proven to make the bullets fire more accurately. In fact, more than three quarters of all medals at the London Olympics were won using these rounds.

Modelling, Sculpting and Casting material

Beeswax has been the major component of Madame Tussauds wax since Marie Tussaud started modelling with it over 200 years ago. While the wax for the heads has changed little since then, other waxes have been developed and refined over the years, with stronger waxes used to prevent fingers being broken off for souvenirs, and even a wax glue for sticking eyeballs in their sockets. Perhaps more importantly, the processes to make the figures and the business behind it has developed immensely. Nowadays it takes about 15 artists three months to complete each wax figure. This highly intensive process even involves inserting each strand of hair individually into the wax head. As part of the Merlin Entertainments Group, Madame Tussauds now has more than 2,000 figures at 24 attractions around the world, all lovingly crafted at their studios in Acton, London.

Courtesy of Merlin Entertainments.

Produced in thin sheets, dental modelling wax is a blend of paraffin, microcrystalline and sometimes beeswax, modified with oil. These sheets are placed in the mouth and bitten onto to create an impression as the first step in making dentures and false teeth. In most cases, beeswax has been phased out, but continues to be used in more specialist grades where hydrocarbon wax formulations don’t quite provide the right physical properties.

Lost wax casting has been used as a technique to produce bronze figures for more than 5,000 years, with some of the earliest examples coming from the Middle East and South Asia. We assume that beeswax was the main wax, later modified by resin, pitch and tallow.

Hydrocarbons waxes have replaced beeswax in most casting waxes – but as is often the case, not all formulations exactly replicate the properties produced with natural waxes. More recently, beeswax has been used in ceramic injection moulding to produce small or complex cavities in investment cast metals. These pieces are predominantly found in aerospace and industrial markets, but there is a growing demand in healthcare, sports and automotive markets.

By our last estimation, beeswax accounts for approximately 0.3% of global wax production, so it will always be a niche product. But operating in the niches can be a satisfying experience and provide good business opportunities. Who knew that waxes could be used to lubricate industrial cement kilns, produce a marking compound for blank training ammunition or seal a luxury bottle of craft gin? And we haven’t even started on special effects glass and ice effects, physiotherapy, the list goes on…

Header picture by Ante Hamersmit – Unsplash

Recent posts

Looking to make your bottles unique and eye-catching?Our bespoke bottle sealing wax is tailored to the customer’s precise specifications, and adds a distinctive touch that enhances quality and…

We’re thrilled to announce that you can now purchase directly through our website with an online checkout!Currently, this e-commerce feature is available for a select…

Sealing wax has a rich and colorful history that dates back centuries, embodying both elegance and function. Originally used to seal important documents and signify…